Pre-treatment

Pre-treatment of components for centrifuge galvanizing is often made in baskets, containers or similar. The result of this treatment is often varying in quality and have long treatment times. Flat details can have contact surfaces that remains untreated. With rotating drums the quality is increased and a good pre-treatment is secured. The treatment time can be reduced with up to 50%.

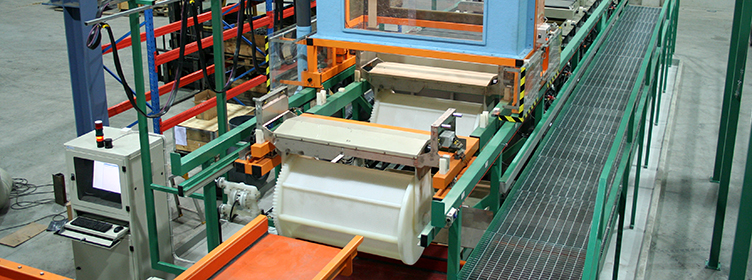

The drums are made of varying materials such as stainless steel, titanium or HD polyethylene. The automatic plant is computer controlled and has a selective process control. It can be equipped with devices for automatic filling and emptying of the drums. This can be integrated with an automatic centrifuge plant without manual operations between the devices. Emissions are contained and evacuated from the process tanks and the transporters through ventilation shafts. The ventilation system with the transporter housing and lids on tubs are part of our PROGA-VENT™-system. It is possible to attach a scrubber for cleaning the extract.